You’ve made the decision to go lean. One of your initiatives for this year is to go forklift free and you have a plan for how to make it happen.

There is a solid plan for where parts will be stored, where they will be used, the packaging they’ll be in, and how to manage the replenishment cycle. Now it’s time for another decision – what kind of carts should you use for your material delivery cart train?

The main criteria for the decision can be broken down into three categories:

- Packaging

- Flow system

- Cycle time

Packaging describes how the parts to be delivered are packaged. Broadly you will have three categories: unpackaged, packed in right-sized container, packed in unique container. Right-sized container in the second category could be anything from a 45”x48” bulk knockdown or gaylord to a 12”x15”x7” hand tote. The distinction is that it’s a small enough container size that there are standard cart references to move it. The third category of unique container is really referring to unique, high requirement, large sized parts – things that are in custom racks or customized dunnage for which you would need a custom cart design. We’re looking for the percentage of parts in each category. If 20% of parts are unpackaged, 70% right-sized, and 10% unique a “standard” cart train will be fine. If 30% are unpackaged, 30% are right-sized, and 40% are unique the answer will be quite different.

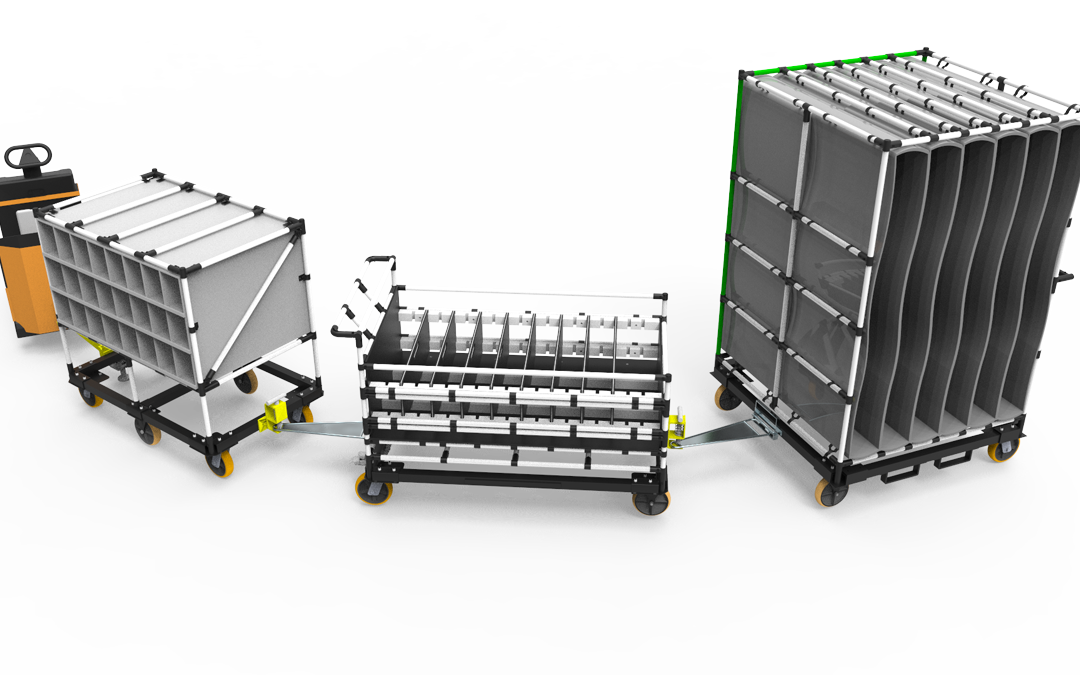

Flow system describes the carts you want to use AND how you want to present material to the operator. Know the interaction you want to see between the three zones of material flow – the aisle where cart trains move, the boundary where carts, live storage racks, and flow equipment present parts to the operator, and the production line / work zone itself. When considering a cart train, there are two types of delivery styles, coupled (where each cart in the train connects to the one in front and behind) and mother daughter (where the mother carts are coupled to each other and the daughter carts are held to the mother carts). The key point to evaluate is how often you will be decoupling carts in the train to move them to the line and swap full with empty carts. If that is happening very frequently, mother-daughter carts are a great option to reduce the burden on the material handling personnel and reduce cycle time. Mother daughter style carts come in a variety of options – corral, gantry frame, E frame, C frame, etc – which will be discussed in a later post. As much as possible, work to standardize the cart base size and customize the “top hat” of the cart which allows movement of unpackaged parts, small boxes, totes, and bulk containers on the same footprint.

Cycle time is where we start to evaluate the load on the people doing the material handling work. Much of this will be dictated by your production environment (high volume [appliance, automotive, etc] vs. low volume [aerospace, capital equipment, etc]) although there will always be variations. An environment with fast production takt times, small boxes holding less parts, and exchanging full and empty boxes from carts to racks generally points towards shorter delivery routes, more people, and coupled trains. An environment with low production takt times, parts being held on kit carts, exchanging full and empty carts at the line points towards longer delivery routes with sequenced drops, less people, and either coupled or mother daughter trains.

Material flow and cart train systems create the macro level of material flow in the plant, with presentation and work space taking flow down to a more micro level. Getting the macro flow right sets up the micro flow for much better success.

In summary, the three elements to evaluate with main considerations:

- Packaging

- Are you moving parts, right-sized containers, or unique containers?

- Flow system

- How do you want to connect the aisle, the boundary, and the line?

- Cycle time

- How often are you moving how much stuff?