LEAN MANUFACTURING ARTICLES

Get inspired and share!LEAN MANUFACTURING ARTICLES

Get inspired and share!Benefits of Customizable Material Handling Carts (Top Hat Carts)

Top hat carts are a customizable material handling solution that can offer versatility and cost-savings to any warehouse or production facility. Simply put, a top hat is a convertible assembly that sits on top of a standard flat top cart deck. This allows your team...

Social Distancing in Manufacturing

In light of the COVID-19 pandemic, manufacturers find themselves in a unique environment and are working hard to adapt quickly. For many, production must continue as you develop essential goods in this time of crisis. To keep facilities online and personnel safe, many...

Live Design to Support Changing Times

The COVID-19 pandemic has created a unique environment for today's manufacturers. Some of Geolean USA's existing tools, such as live design, have become even more valuable to our clients today, as we work to support manufacturers implementing social distancing...

Custom Delivery Carts in the Warehouse – Geolean Warehouse Solutions

Previous installments of the "Geolean Warehouse Solutions" series have focused on incorporating flow racks into pallet racking and customizing workstations for packaging and simplified order processing. The next logical consideration when looking at ways to improve...

Efficiency With Custom Workstations – Geolean Warehouse Solutions

In the first article of the "Geolean Warehouse Solutions" series, we talked about making your pallet racking work for you by incorporating flow racks. Once your pallet racking is squared away and “flowing” properly, you can move on to the value-add areas of your...

Flow Racks in the Warehouse – Geolean Warehouse Solutions

Flexible warehousing is a hot topic in the warehousing industry today. More and more companies need to store high-turnover inventory for short periods of time. Add that to the fact that companies are trying to do more — more production and more product output — with...

How To Easily Implement a Shadow Board In The Workplace

A custom shadow board organizes your workspace by creating the perfect place for every tool and visually indicating when these tools are missing. Mechanics and operators won't need to search around to find the right tool, and workstations will be clean and organized...

How Does Lean Manufacturing Improve My Bottom Line?

So, you're interested in pursuing lean manufacturing. Maybe some of your competitors have implemented lean strategies with success, or maybe you know it's your only option to efficiently integrate that new product line into your facility. It's clear that lean...

6 Questions To Ask A Lean Manufacturing Consultant Before Hiring

Hiring a lean manufacturing consultant isn't an easy task. “Consultants” are often viewed as “armchair quarterbacks”; having strong opinions about every play made yet having little or no skin in the game to actually affect the outcome. But if you're serious about...

5 Cart Applications to Improve Material Flow in Manufacturing Plants

Material handling carts are used to improve material flow through any operation. However, even operations that use carts effectively sometimes struggle to identify good cart applications. They use too many forklifts, move things manually, or have stagnant inventory....

The Value Of Your Lean Implementation Is Equal To Your Ambition

Lean can be effectively applied at any scale of time or space. Action implemented in a span of one minute or one decade. A system coordinated between five cells or five countries. The incredible power of lean is the power of scale. It’s also an incredible weakness....

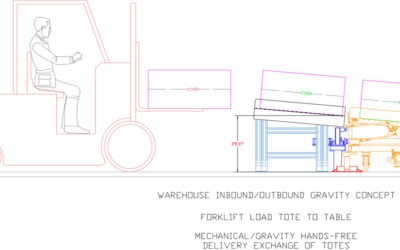

Supporting Hands-Free Material Delivery

Geolean supports our clients by designing and installing systems that create flow. Flow of materials and information is the best way to create durable improvements in safety, quality, and productivity. Correctly designed flow systems improve operations today and build...

How Flow Concepts Improve Operator Health and Safety

You can hear the health, safety, and environment (HSE) team from the next room - flow? What does flow have to do with me? Maybe more than you realize. HSE has a big job to do. The health and safety of operations personnel during normal production operation...

What Does It Mean To Engineer Material Flow?

The best way to understand engineered material flow is to consider the opposite. Randomly moving stuff, expedited! is one we encounter often. What is engineered material flow? A correctly designed material flow system is dynamic, interactive, and...

Create Better Material Flow With Effective Flow Rack Design

Flow racks are critical equipment to a healthy material flow system. A previous blog highlighted uses for flow racks and how they could be used to improve material flow, so now is the time to get into the detail of how they should be designed to work effectively. This...

Why Manufacturing Workstation Design Matters

When I walk into your plant, the attitude of the people and their interaction with their work environment is a quick indicator of your company’s attitude. Too often there are frustrated people struggling in a poorly designed environment with equipment poorly suited to...

Lean Lessons From Food: Taste The Ants, Flow The Juice

There is an enjoyable Netflix documentary called “Chef’s Table”, and I had a chance to catch a few episodes this weekend. The show provides great insight into the working patterns of amazing chefs along with the context of their pursuit of the profession. There’s not...

Forklift free: Apply three rules for a successful implementation

Fork truck free / forklift free is all the rage right now. Every industry publication, trade show discussion group, and cart manufacturer in the country is talking up the benefits of eliminating forklifts. It’s like Industry 4.0 - except it actually works. For...

What is a Mother Daughter Cart System?

One of our key phrases at Geolean is “Get the fork outta here!” When we work with clients to create their lean system, removing forklifts from the manufacturing area is a point of emphasis. Getting rid of forklifts makes sense, but it’s not always an easy change...

Hidden Benefits to Installing a Lean Manufacturing and Lean Management System

Almost all of our customers believe in lean and would say they have a fully integrated, operational lean system. At some point though, when they’re far enough on the lean journey, they start to ask themselves if there wasn’t something they missed somewhere along the...

DOES YOUR MATERIAL FLOW NEED IMPROVEMENT? WE CAN HELP!

IS YOUR FACTORY A GOOD FIT FOR LEAN INTEGRATION?

Fill out our lean integration checklist to determine if your factory might be ready for lean integration.

THE COMPLETE

GUIDE TO LEAN INTEGRATION

Here's everything you need to know broken down into manageable parts that are easy to implement.

IS YOUR FACTORY A GOOD FIT FOR LEAN INTEGRATION?

Fill out our lean integration checklist to determine if your factory might be ready for lean integration.

THE COMPLETE

GUIDE TO LEAN INTEGRATION

Here's everything you need to know broken down into manageable parts that are easy to implement.

STAY UP-TO-DATE WITH GEOLEAN USA

Sign up to receive updates from our lean trends blog and newsletters