by Tim Floyd | Apr 9, 2018 | Lean Solutions

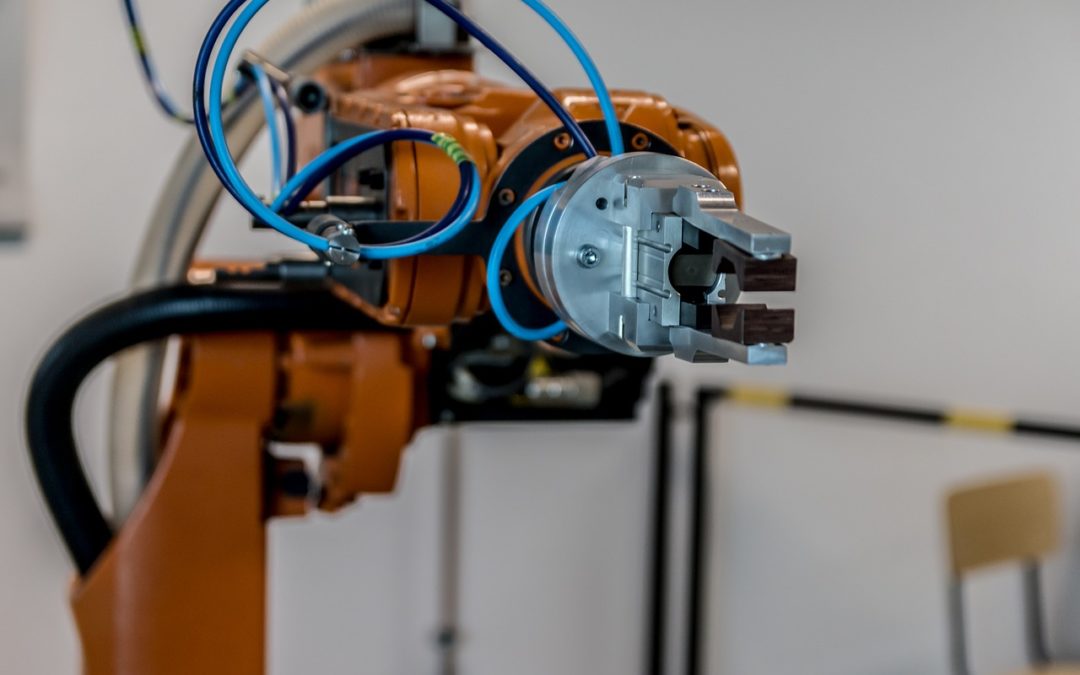

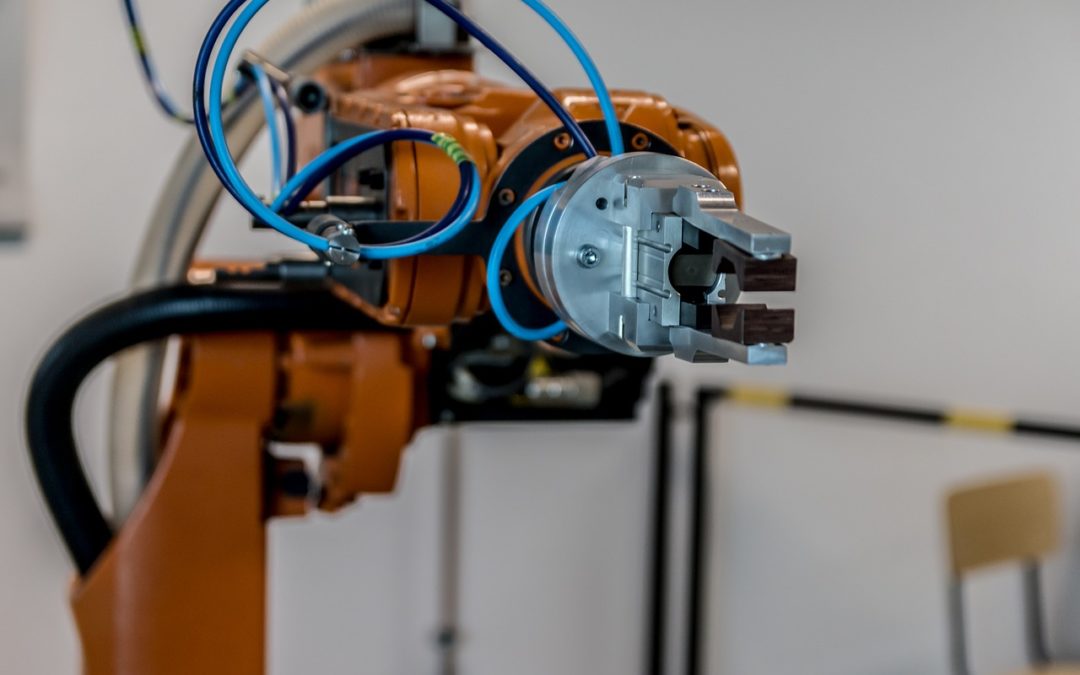

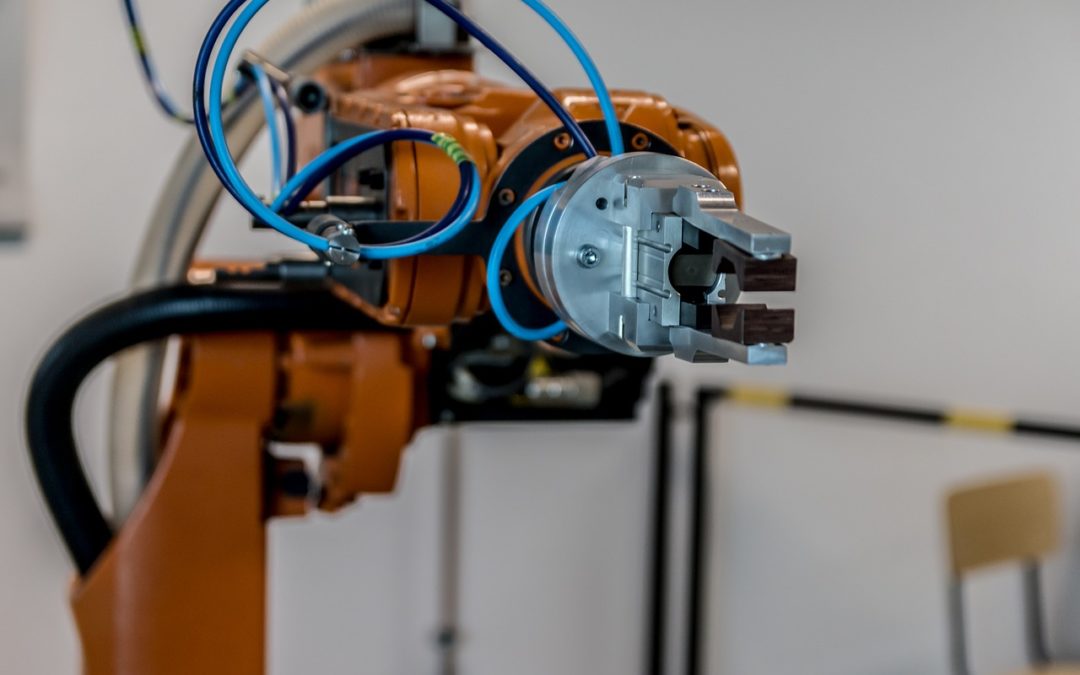

Robots never get tired. Robots never make mistakes. Robots don’t get injured. Robots don’t take vacations, sick days, or lunch breaks, and they never complain. Automation seems to solve nearly every problem attributed to people in many areas of our lives. But in truth...

by Tim Floyd | Mar 27, 2018 | Flow Racks

Flow racks are an important but under considered piece of equipment. They present product clearly, enable small box packaging, and support pull and FIFO systems. Good flow racks can have huge benefits in safety, productivity, and delivery. Here are the major things...

by Tim Floyd | Mar 23, 2018 | Lean Implementation

There’s ongoing discussion in the lean community about where to start transformation projects. It’s an important debate because of how often lean implementations fail and the toll the failures take on people, companies, and the positive understanding of lean. Hard...

by Tim Floyd | Mar 15, 2018 | Lean Solutions

Lean manufacturing is all about becoming more effective and efficient. Applied correctly, the lean system will improve all operational metrics on the way to achieving greater efficiency. Applied incorrectly or with too much emphasis on production, other metrics like...

by Tim Floyd | Mar 6, 2018 | Continuous Improvement

Although the terms lean manufacturing and continuous improvement are thrown around and used interchangeably, they are not the same. Lean manufacturing is a business operating system, originating from the Toyota System, with applications across industries. Continuous...