Manufacturers across the nation are looking for faster, more efficient ways to streamline processes and production. While automation seems to be top of mind for most, it’s also an expensive investment that some may not be ready to take on. Luckily, there are other solutions you can implement to improve your manufacturing facility’s efficiency.

Karakuri kaizen, or karakuri, provides low-cost, simple, hands-free solutions to support manufacturers’ needs. Let’s take a closer look at what it is and how it can benefit your facility.

What Is Karakuri?

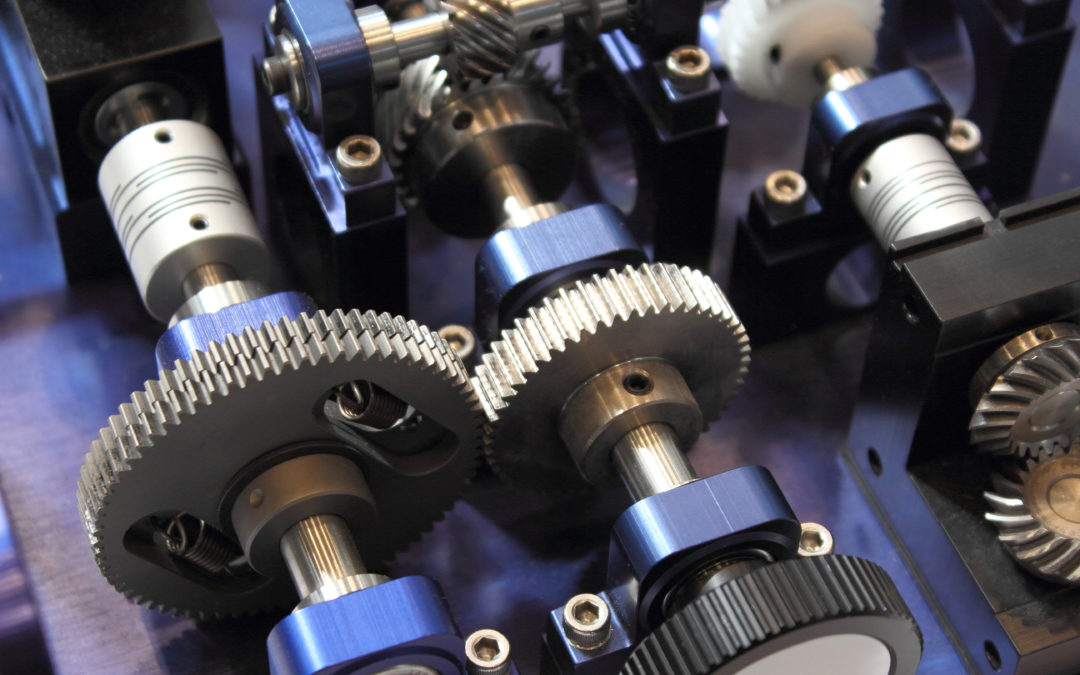

Karakuri is a Japanese term that refers to a lean methodology involving simple, mechanical material handling devices that rely on gravity and inertia to move product across a facility. Instead of using computers, hydraulics, gas, or other expensive sources of power, karakuri employs low-cost mechanisms like springs, levers, gears, and pendulums to do the work.

Karakuri offers a more affordable streamlining solution for manufacturers, while also delivering a people-centered product that promotes ergonomics and continuous improvement.

What Are the Benefits of Karakuri?

Although karakuri may be new to many manufacturers, its benefits are plentiful — making it a worthwhile ideology to adopt. Below, let’s walk through four of the main benefits it brings to facilities around the world.

Low-Cost

Let’s be honest — every product or solution pitch begins with “low cost.” Therefore, it’s important to consider all aspects of each system’s cost during planning to really break down which is best for you. Be sure to consider the following questions:

- What are the upfront and total design costs of each option?

- What is the development timing to install and utilize each option?

- What do maintenance costs look like, and can we service the solution ourselves?

- What energy and cost will be required to modify each option for future configurations?

After answering each of these questions, you’ll usually find that karakuri’s overall cost is one of the lower options.

Simple to Maintain

In Japanese, karakuri literally means a type of doll or device that moves with simple mechanics. But that simplicity factor doesn’t just relate to operations; it also relates to maintenance.

When discussing ways to create efficiency in manufacturing, it’s important to consider if your system’s maintenance can be done with in-house personnel or if it will require a third-party resource. This will affect how much production downtime you’ll have to endure during regular maintenance and servicing, so simplicity is key.

Ideal for Continuous Improvement

The desired end result of any lean material handling system is efficiency — but, as mentioned in the points above, you also need to ensure your system supports future state planning as well. No matter which industry you work in, your facility’s needs will change, and the right solution needs to be adaptable from the get-go.

Deliver Safety and Ergonomics

Don’t forget the main objective here! Your system needs to deliver products efficiently and safely.

Karakuri is all about supporting the operator through simplicity, so their job is easier and safer. So while you consider the benefits related to development, installation, maintenance, and versatility, understand that human efficiency, ergonomics, and safety are at the heart of karakuri.

3 Great Examples of Karakuri from the Geolean Team

Interested in seeing karakuri principles in action? Take a look at three karakuri examples we’ve used at Geolean!

Tilt Basket

A tilt basket design, also known as “tilt to fill” (TTF) and/or “tilt to return” (TTR), is a mechanical feature that facilitates the rapid exchange of full containers to your operator without the need to lift. Simply send the empty container to a return lane and meter in a single full container with a simple tilt of the basket. Download the Product Spotlight below to see more tilt basket examples!

Pulley-Actuated Drop Gate

How many containers of product do you need on your flow rack, and how can you move them most efficiently? One example, also shown in the Karakuri Product Spotlight above, demonstrates a very simple multi-level flow rack design, where containers flow by gravity as parts are consumed. The weight of each full container alone allows a pre-metered pulley system to flow containers, allowing for additional inventory through a “Z-Rack” style design.

Foot-Actuated Tilt-to-Fill

No hands? No time? No problem! Keeping with the spirit of the solutions described above, there are many simple, mechanical ways to flow your containers efficiently. Consider a foot-actuated gate that will cycle your containers in or out without bending or lifting, all while your hands remain free to work.

.

.

Let the Geolean team show you the most simple, low-cost options to flow your materials — and, when possible, do it hands-free! Learn more about our lean streamlining solutions by giving us a call or contacting us online today.