This past July (2020), Geolean USA conducted a brief State of Manufacturing survey to better understand the unique production challenges manufacturers are facing as a result of the Covid-19 virus. Surveys went out to nearly 4,000 contacts across 800 diverse North American manufacturing companies, with the assumption that we are all asking very similar questions at this time and would all value the resulting insight.

Circumstances over recent months have us using new idioms like, “social distancing”, “the new normal”, and “hold my Corona”; but what remains constant and essential is the need to adapt to change. It’s time for manufacturing to get back on track, and the global Geolean team is committed to supporting change for manufacturers and to ensure that change is successful.

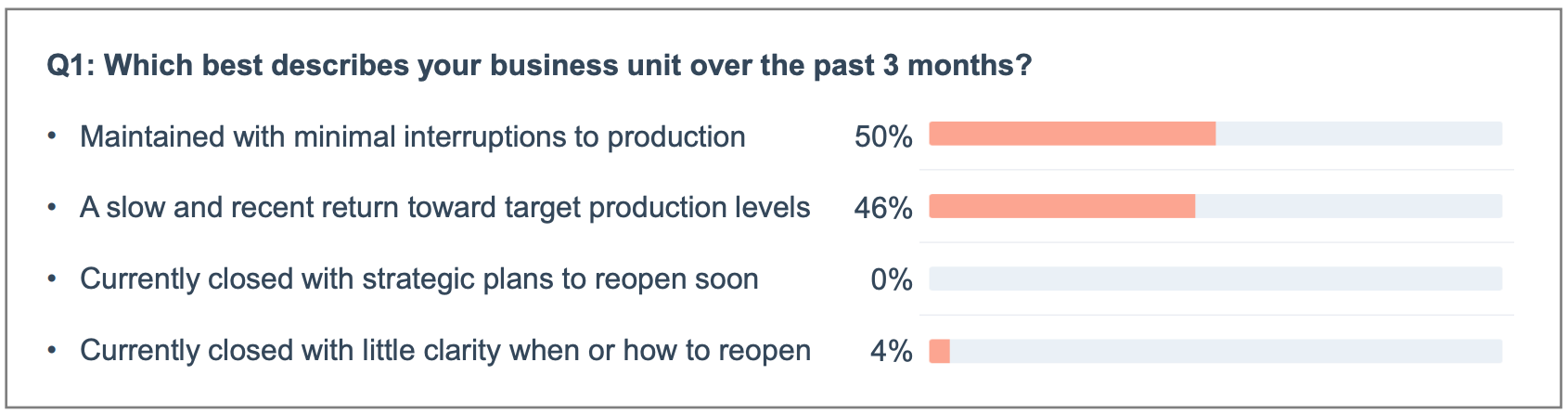

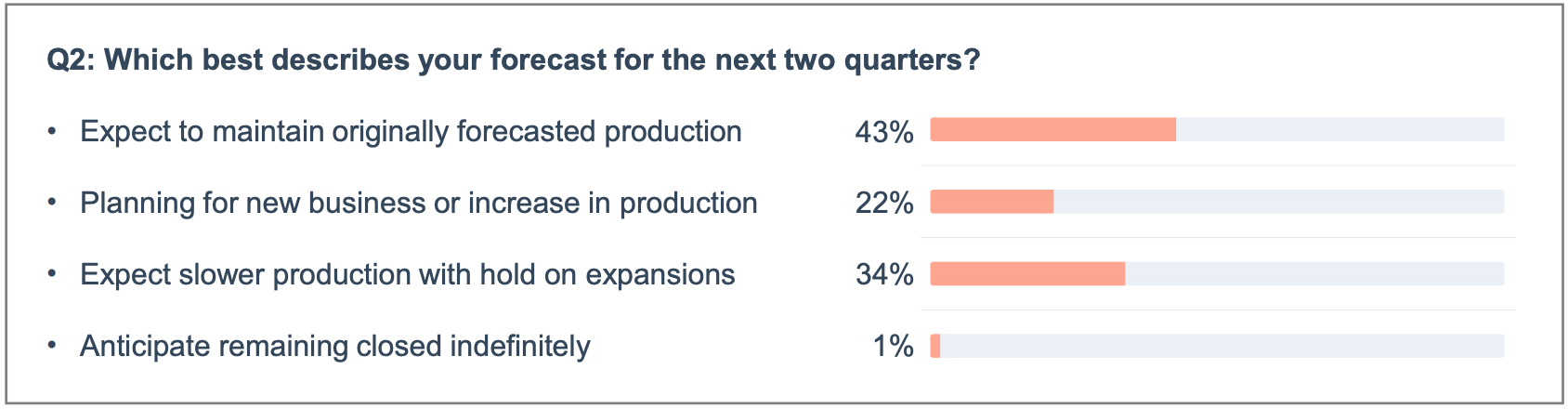

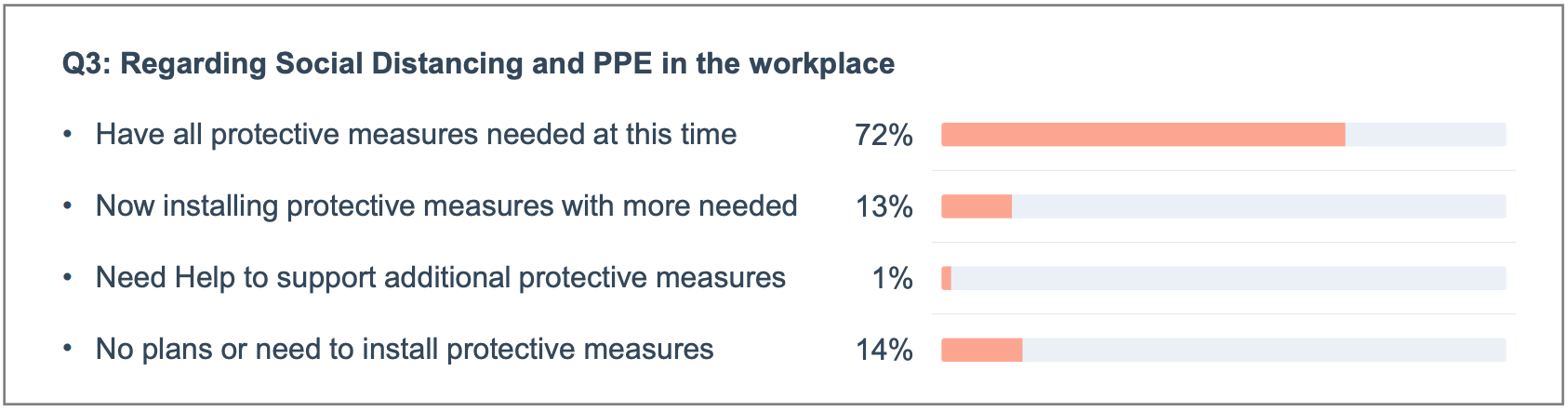

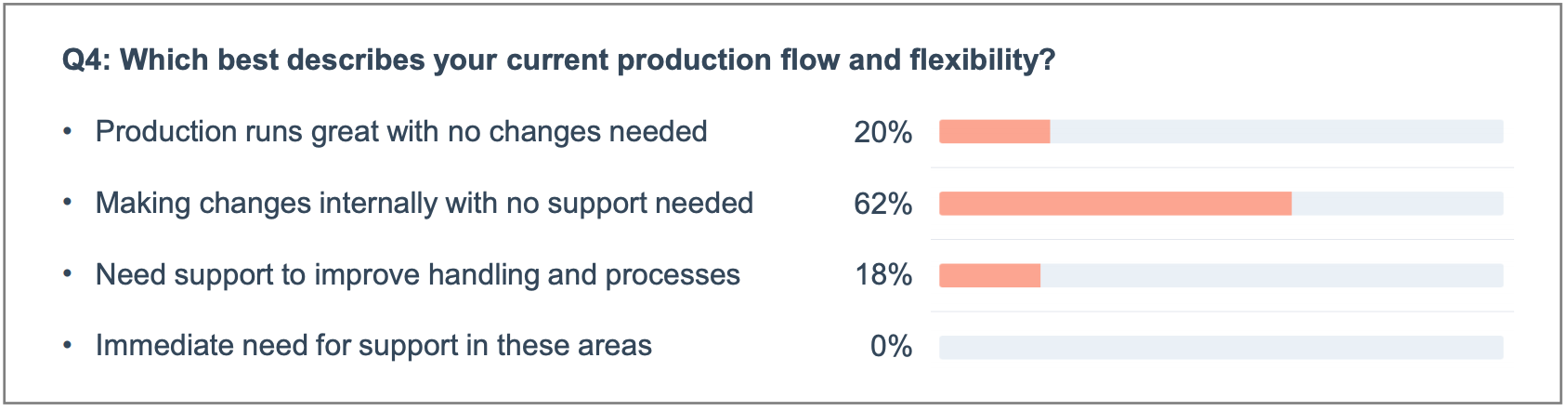

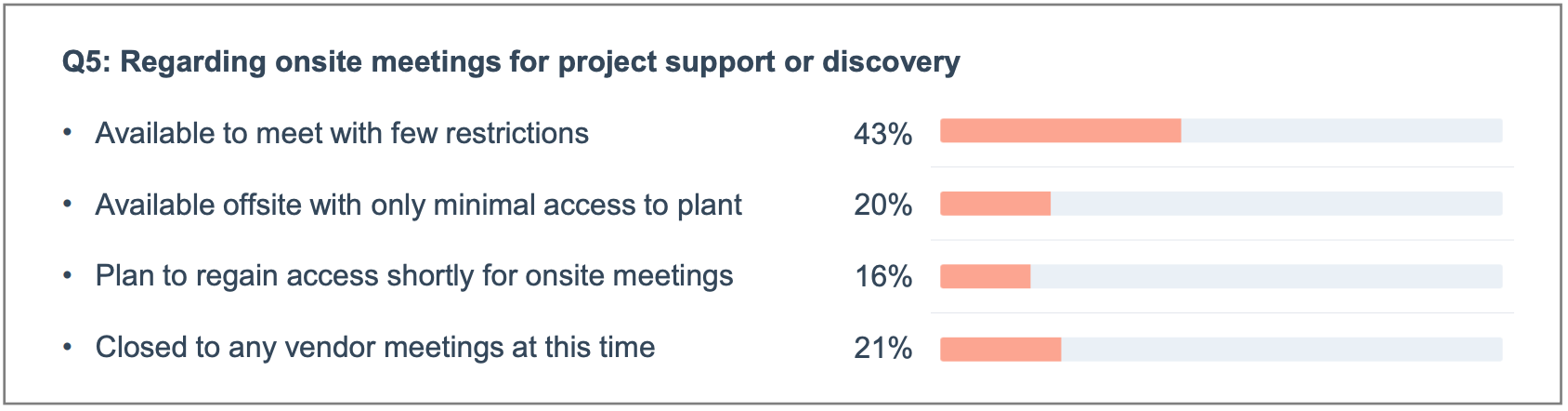

The survey was comprised of 5 multiple choice questions and a field to share specific insight to challenges of productivity . That being said, please consider the following responses on the current state of manufacturing:

From our perspective, the responses to this exercise demonstrate an overall optimistic outlook for manufacturing and an expectation that demand is still high for the months ahead of us.

One final question was asked on the survey, to help us categorize specific productivity challenges that participants are facing and hopefully gain insight to possible trends. The Top 5 most common answers are summarized below and listed in order of highest to lowest based on the quantity of similar answers received.

Q6: What is your greatest productivity challenge today?

- Inconsistent customer demand causing inefficiencies in production

- Personnel challenges related to poor attendance, new employee recruitment, and inefficient work from home initiatives

- Supply chain interruptions causing shortages in material for production

- Funding challenges for improvements caused by delays in the capital approval process and budget cuts

- Social distancing efforts have impeded productivity on the line and limited support that is required in the plant from outside vendors

Winston Churchill said, “To improve is to change; to be perfect is to change often.” We trust this information is of value as you continue forward in your mission. The Geolean family sincerely appreciates those who offered their valuable insight, and we extend our support to those who are working diligently to adapt change.

For more information on engineered material flow solutions for your plant, including custom cart systems, workstations, flow racks, and expert lean production support, please contact Geolean USA today!