INNOVATIVE LEAN INSIGHTS

Your go-to resource for mastering material flow, curated by experts. Gain the knowledge you need to boost efficiency and stay ahead.INNOVATIVE LEAN INSIGHTS

Your go-to resource for mastering material flow, curated by experts. Gain the knowledge you need to boost efficiency and stay ahead.Supporting Hands-Free Material Delivery

Geolean supports our clients by designing and installing systems that create flow. Flow of materials and information is the best way to create durable improvements in safety, quality, and productivity. Correctly designed flow systems improve operations today and build...

How Flow Concepts Improve Operator Health and Safety

You can hear the health, safety, and environment (HSE) team from the next room - flow? What does flow have to do with me? Maybe more than you realize. HSE has a big job to do. The health and safety of operations personnel during normal production operation...

What Does It Mean To Engineer Material Flow?

The best way to understand engineered material flow is to consider the opposite. Randomly moving stuff, expedited! is one we encounter often. What is engineered material flow? A correctly designed material flow system is dynamic, interactive, and...

Create Better Material Flow With Effective Flow Rack Design

Flow racks are critical equipment to a healthy material flow system. A previous blog highlighted uses for flow racks and how they could be used to improve material flow, so now is the time to get into the detail of how they should be designed to work effectively. This...

Why Manufacturing Workstation Design Matters

When I walk into your plant, the attitude of the people and their interaction with their work environment is a quick indicator of your company’s attitude. Too often there are frustrated people struggling in a poorly designed environment with equipment poorly suited to...

Lean Lessons From Food: Taste The Ants, Flow The Juice

There is an enjoyable Netflix documentary called “Chef’s Table”, and I had a chance to catch a few episodes this weekend. The show provides great insight into the working patterns of amazing chefs along with the context of their pursuit of the profession. There’s not...

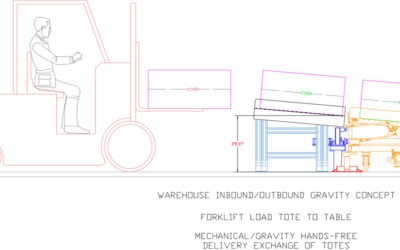

Forklift free: Apply three rules for a successful implementation

Fork truck free / forklift free is all the rage right now. Every industry publication, trade show discussion group, and cart manufacturer in the country is talking up the benefits of eliminating forklifts. It’s like Industry 4.0 – except it actually works. For...

What is a Mother Daughter Cart System?

One of our key phrases at Geolean is “Get the fork outta here!” When we work with clients to create their lean system, removing forklifts from the manufacturing area is a point of emphasis. Getting rid of forklifts makes sense, but it’s not always an easy change...

Hidden Benefits to Installing a Lean Manufacturing and Lean Management System

Almost all of our customers believe in lean and would say they have a fully integrated, operational lean system. At some point though, when they’re far enough on the lean journey, they start to ask themselves if there wasn’t something they missed somewhere along the...

What is Tube and Joint Design?

If you’ve been keeping up with the latest trends in lean equipment solutions (or if you’ve just been keeping up with our articles), you know that tube and joint design is widely applied to create effective material flow solutions. But what is tube and joint design?...

Understanding Manufacturing Bottlenecks Part 2: Flow Through

Our previous article introduced the three main categories of bottlenecks that apply to a manufacturing operation: demand in, people around, and flow through. Part 1 of this series went deeper on the subject of demand in. This article will discuss the...

Understanding Manufacturing Bottlenecks Part 1: Demand In

Our previous blog introduced the three main categories of bottlenecks that apply to a manufacturing operation: demand in, people around, and flow through This article will discuss the subject of demand in more detail, along with how to understand and think...

Visualize a Connected System to See Manufacturing Bottlenecks

There are only three manufacturing bottlenecks that matter: demand in, flow-through and people around. They all connect to each other and any other apparent bottleneck can be grouped under one of these primary bottlenecks. A bottleneck is a step or point in a process...

5 Manufacturing Problems That Can Be Solved With Lean

As lean integrators, we’ve seen all types of manufacturing and production operations and all sorts of issues that prevent those operations from achieving their next level of success. Here are a few common issues we see and insights into how lean can be applied to...

How To Create A Lean-Friendly Company Culture

It’s fun to go on benchmarking trips. It’s fun to go see Toyota or Toyota-inspired operations in Japan. Everyone comes back from those experiences with a head full of “what could be” and ideas on what to change, all at the same time. Then they get back to...

What Are Tugger Cart Systems And How Do They Improve Material Flow?

One of our key phrases at Geolean is “Get the fork outta here!” When we work with clients to create their lean system, removing forklifts from the manufacturing area is often one of the first initiatives. Getting rid of forklifts makes sense, but it’s not always an...

Why Your Manufacturing Workstation Needs a Makeover

You might think you’re doing it all right in terms of applying lean manufacturing principles in your factory: you’ve visualized processes, are working to go forklift-free, and you’ve got buy-in from top management. But if you’re just using standard catalog...

What are Flow Racks and How do they Improve Material Flow?

There are four main groups of physical equipment that support material flow: carts, workstations, packaging, and flow racks. Of those four groups, flow racks are the least understood. It may be because the others are encountered in normal life - if you go to any...

See your Plant Like a Monopoly Board

I was walking a customer’s plant recently and trying to convince them why they should switch to small totes from large bins. We discussed the benefits to operator ergonomics, product mix, production scheduling, material delivery, inventory, and on and on....

AI is No Match for NS

While enjoying some lakeside time I saw a beverage koozie with a great phrase: “Artificial intelligence is no match for natural stupidity”. I have a very positive outlook on the potential for any person to grow and develop from their current capability. I also have a...