INNOVATIVE LEAN INSIGHTS

Your go-to resource for mastering material flow, curated by experts. Gain the knowledge you need to boost efficiency and stay ahead.INNOVATIVE LEAN INSIGHTS

Your go-to resource for mastering material flow, curated by experts. Gain the knowledge you need to boost efficiency and stay ahead.Boeing’s Bombardier Airbus’ Unintended Consequences

The impact of unintended consequences are felt long after they are first recognized, and the impact of the Boeing-Bombardier-Airbus news this week will be felt for decades. The most recent outcome is a tie-up between Airbus and Bombardier’s C Series jet program,...

The Power of Flow, Demonstrated in Donuts

I'm a big donut fan. When I'm in your city, I'm searching out the local hotspot to test the best. As an invention, donuts are up there at the top. Maybe flight is better, but only by a fraction. Took a weekend trip to upstate NY this summer and found a...

Treat your capital budget like a nice steak – leave the fat in

"The root of my success is acting rationally about capital allocation" - Warren Buffett As the weather here starts to turn and we enter the fourth quarter of the calendar year, two separate cycles combined in my mind. The cool weather creates perfect...

Don’t start the layout until you know the process

Do you feel like you’re in an infinite loop of frustrating layout changes as you keep changing process elements? It’s probably because you started layout planning too soon. Two quotes on this subject from Chihiro Nakao, from the book Kaizen Forever “Build...

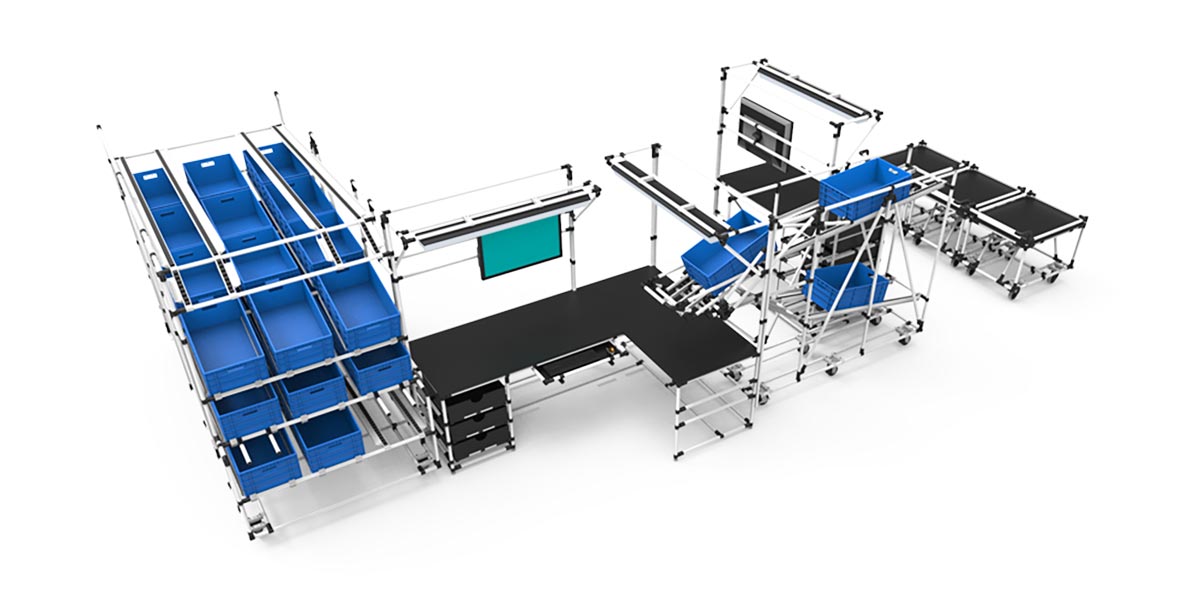

3 Steps to Better Material Flow — Connect Your System

You’ve made the decision to go lean. One of your initiatives for this year is to go forklift free and you have a plan for how to make it happen. There is a solid plan for where parts will be stored, where they will be used, the packaging they’ll be in, and how to...

Lean is not an investment, it’s a decision

We hear this question all the time – “What will my payback from lean be?” The payback will be tremendous, the increase in capability will be tremendous, the impact on your environment will be tremendous, the impact on your people will be tremendous. It can start as an...

One Piece Flow Everything, Everywhere

One piece flow everything, everywhere. There’s a lot of assumptions baked into that statement. An assumption that one piece is the right quantity, that flow is the most efficient condition, and that it has universal application. We shouldn’t take those...

Lessons in the Toyota Production System (TPS) – from Panera?!

The “fast casual” restaurant category may be the furthest thing from automotive production, but a recent article in the Wall Street Journal perfectly captures the application of Toyota Production System (TPS) principles to this industry. It’s a fun illustration of why...

4 In’s and 1 Out – 5 Material Flows to Know

Every warehouse, manufacturing plant, production facility, and logistics operation – no matter where they are or what they do – has to manage the same 5 kinds of material and information flow. Your success will be determined by how well you design and integrate these...

Lean Lessons in the News

Click on the headings below for links to full news articles Tool and Die – Manufacturing canary in the coal mine? IndustryWeek recently posted an article on the tool and die industry that's worth a read. The manufacturing ecosystem depends on healthy tool and...

5 Signs Forklift Free Is A Must For Your Operation

There is clear support for the safety, resource efficiency, and productivity of forklift free / fork truck free initiatives. Those elements show why the initiative is important, but they don’t always create the clear moment of insight into your operation and why it...

Is Your Material Flow Based on Chaos or Consistency?

There are three choices to plan your material flow system: 1. Fixed time, variable quantity 2. Variable time, fixed quantity: 3. Chaos Any of the choices are valid depending on the context they are used in, and you’ll always have some element of each. The important...

Create Flow by Going Forklift Free

Forklift / fork truck free initiatives are everywhere. Either you’ve done it, you’re doing it, or you will be doing it soon. There are too many reasons not to, which I outlined in the "Why?" aspect of forklift free in our series. While all of those points are...

Eliminate Forklifts – Commit to Safety, Improve Efficiency, Reduce Cost

Commit to Safety Imagine forklifts driving around a school, hospital, or mall. Sounds crazy, right? So why would you tolerate forklifts driving around your work place? All companies say they prioritize safety, but we see fork lifts driving around plants and factories...

Get the Fork Outta Here! Forklifts, that is – Part 3

This is part 3 of a multi part series. Read part 1 for background on forklift usage, and part 2 for our perspective on why going forklift free should be an operational priority. Part two of this series introduced two perspectives on the forklift free subject - one...

Get the Fork Outta Here!

Forklifts, that is – Part 2

This is part 2 of a multi-part series. Read part 1 for background on forklift usage. There are generally two viewpoints related to forklift free / forklift restricted initiatives – one viewpoint understands it and are trying to figure out how to implement it, one...

Get the Fork Outta Here! Fork lifts, that is – Part 1

Eliminate fork lifts from all work and walk areas. Fork lift elimination from personnel zones should be the priority goal shared by leadership, health-safety-environment (HSE), and materials management – this applies to all industries, but manufacturing, production,...

Prioritize Improving

Your Internal Logistics System

I see different production and office environments every week, and all of them represent opportunities for improvement. A common theme is the subject of “Where to start?” If we split any work area up into two oversimplified categories you have 1. The work being...

Don’t think – Act! – with Customers in Mind

What is the purpose of a business? Focus, focus, focus on the customer. There are five fundamental components to a business, in descending order of importance: Customers Employees Products Suppliers Shareholders Of course there are other critical, necessary, and...

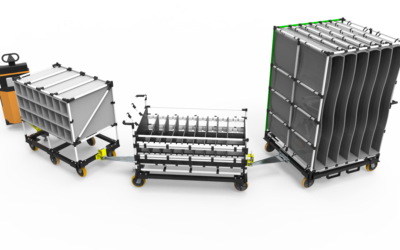

Geolean Global News: Create Superior Material Flow with Integrated Carts

Integrate Part Protection and Material Flow Carts with integrated part protection are a great way to control and manage WIP inventory. Instead of double handling WIP parts by putting them in a container, storing that container, and then putting that container on a...