INNOVATIVE LEAN INSIGHTS

Your go-to resource for mastering material flow, curated by experts. Gain the knowledge you need to boost efficiency and stay ahead.INNOVATIVE LEAN INSIGHTS

Your go-to resource for mastering material flow, curated by experts. Gain the knowledge you need to boost efficiency and stay ahead.Scaling Smarter: How Lean Manufacturing Helps Data Center Suppliers Keep Up with AI Demand

When OpenAI publicly released its first large language model (LLM) in November 2022, it ignited a global wave of generative AI adoption that has fundamentally reshaped how technology—and the infrastructure behind it—scales. From predictive analytics to autonomous...

A Guide to Implementing a FIFO Storage System in Lean Production Environments

In lean manufacturing, every detail of material flow matters. One of the most effective methods for maintaining smooth operations and minimizing waste is the FIFO (First In, First Out) storage system. By ensuring the oldest stock is used first, FIFO reduces the risk...

Uncovering the Secrets Behind the Most Successful Lean Warehousing Operations

Warehouse managers face relentless pressure to optimize every square foot, every labor hour, and every movement of material—all while supply and demand shifts in unpredictable ways. Lean warehousing provides a proven approach to addressing these challenges directly....

The Power of Lean MRO: How It Drives Results in Aerospace Applications

Maintenance, Repair, and Overhaul (MRO) operations are the heartbeat of aviation performance, keeping aircraft flying safely and critical equipment running at peak levels. In an industry where downtime costs millions and safety is paramount, MRO is not optional—it’s...

Warehouse Order Picking: Flow Rack Solutions and Material Flow Strategies to Improve Efficiency

Order picking is one of the most labor-intensive and costly operations in any warehouse. It’s estimated that picking alone can consume up to 55% of a distribution center’s total operating costs. Given the high labor demands and the need for precision, optimizing...

Investing in Lean Manufacturing Equipment: Why It’s a Smart Move Amid Fluctuating Tariffs

In today’s rapidly evolving industrial landscape, manufacturers face a myriad of challenges, from rising costs to supply chain disruptions. These daily challenges were recently overshadowed by the implementation of a new and fluctuating tariff regime. While the...

How to Optimize Pick, Pack, and Ship Processes with Material Flow Solutions

The pick, pack, and ship process is the foundation of a fulfillment operation. . Each phase plays a critical role: picking ensures the correct items are selected, packing safeguards products for transit, and shipping guarantees timely delivery to customers. But it’s...

Industrial Tuggers 101: What They Are, How They Work, and Why You Need Them

Across industries and applications, material flow is a critical driver of facility productivity. How efficiently components move from one stage of your process to the next directly impacts operational costs, cycle times, and throughput. As more companies prioritize...

How to Improve Your Lean Manufacturing Processes in Less Than 90 Days

Improving your facility’s operational efficiency can have a significant impact on your bottom line. However, it can take a long time to see and feel real results. Why? Because many lean manufacturing providers spend too much time in the sales process. You may...

Quality, Price, or Service: Which Matters Most for Lean Manufacturing Services?

Most companies try to be everything to everyone— claiming to provide better quality, service, and prices than their competitors. However, after decades in lean manufacturing consulting services, the Geolean team understands the importance of focusing on specific...

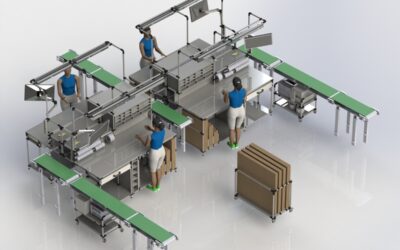

Navigating the Cellular Manufacturing Journey: Creating a Model Cell or a Cell to Model?

As organizations set out on a cellular manufacturing journey, a critical question emerges: Are you seeking to create a manufacturing model cell, or are you striving to cultivate a cell that will serve as a blueprint for future operational excellence? This distinction...

Effective Workstation Design: 5 Key Features to Consider

Designing a workstation is not about creating a physical structure; it's about crafting an optimized space tailored to specific tasks, workflows, and user needs. Whether you're setting up a desk for logistics processing or creating an inspection or packing station,...

Discover the Power of the Geolean System: 6 Benefits from Real Customers

At Geolean, we take pride in providing comprehensive material handling solutions that optimize operations for our clients. Let's delve into real-life use cases where our system brought tangible benefits to our customers. 6 Ways Geolean Optimizes Operational...

Balancing Production Flow & Ergonomics: How to Craft the Perfect Recipe

In the world of modern manufacturing, achieving a balance between material flow and ergonomic considerations can be tough. The relentless pursuit of cramming more material into confined spaces often leads to an undesirable compromise between efficiency and worker...

Purposeful Packaging & Material Flow Systems in Lean Manufacturing

Packaging serves a multi-faceted role within the manufacturing and logistics industries. Beyond its primary function of protecting parts, the choice of packaging material, design, and process has far-reaching implications for cost, sustainability, and overall...

Short-Term Disruption From UAW Strikes = Long-Term Opportunity To Improve Your Manufacturing Material Flow

Could the current UAW disruption be your opportunity to improve material flow? Discover 3 areas you can quickly improve! The UAW's decision to initiate a strike, or any large-scale industry-wide transformation, can send shockwaves throughout the manufacturing...

Discover What Makes Geolean USA Different

Geolean USA is a globally-recognized leader in installing lean methodologies and is deeply committed to enhancing people, processes, and products to enable manufacturers to succeed. With our transformational approach, Geolean has facilitated over 200 successful lean...

How Kit Carts Could Benefit Your Operation

Geolean is proud to provide a range of kitting carts catering to all delivery requirements. Whether you want to save space, transport items, or improve the efficiency of your operations, Geolean has you covered. We’ll dive into the benefits of kit carts and their...

Getting Started With Tube and Joint Systems

Getting Started With Tube and Joint Systems Continuous changes in consumer demand require manufacturers to stay on their toes and be adaptable. If you’re working in antiquated workspaces or using outdated equipment, you may be inhibiting your company’s ability to...

How to Implement Flexible Material Handling Solutions

Manufacturers and warehouses everywhere are looking for methods to implement greater efficiencies without adding cost. Automation is at the forefront of all of our minds here, but implementing tech-heavy automation is easier said than done, and calculating ROI can be...